Motion Sensor Control – Motion Detector Trigger

Version: 1.1

Last Update : 10/19/2009

This document contains notes

to myself that allowed me to construct the motion sensor control. Instructions within this document are notes

to myself and recommend steps to myself. Anyone using this document to

construct a motion sensor control does so at their own risk.

Beware;

this document is intended only for people with electrical and electronic

project skills and the knowledge of the involved hazards to property and to

life forms including people, and the necessary safety procedures. Use the

information here only at your own risk.

The

use of the motion sensor control is at the

user's sole risk. By purchasing the components to build the motion sensor control, the purchaser/builder

understands that the motion sensor

control

is intended for educational purposes and any use of this information,

components, or completed project is at the user’s own risk. The

creator/supplier of this information and components shall not be liable for any

damages or personal injury from the use of the motion sensor control.

Then store bought motion

sensor has specific specifications that should be adhered to, namely the

control is rated 120v AC, 60hz, 4.2amps, max 300-500 watts depending on the

sensor. The project is using a house hold extension cord. The household

extension cord is a 16 gauge wire, two conductor (no ground) rated 125v, 1625

watts. Here are some extension cord safety tips - http://www.cpsc.gov/cpscpub/pubs/16.html

The information contained in this document is not to

be redistributed.

Tools Required

Note: not all tools may be

required if some of the components have already been prepared.

Phillips Screw

Driver

Black Tape

Wire Cutters

Wire Strippers

Components - Supply List ($20)

Reference Figure 1 for a

picture of each component. Note: not all components will look exactly like what

is pictured in this document. The outlet box might be a different color, the extension

cord might be a different color, length, etc. This goes for all of the

components.

(A) 1 – single

outlet box (gang box, wall box) ($1)

(C) 1 - outlet box

cover (.50)

(D) 1 - extension

cord – 125VAC, 16/2 gauge ($1)

(Z) 1 Replacement

Motion Sensor (detector) ($10-13)

Prices are approximations.

Motion sensor can be purchased at Menards ($10) and Meijer ($13). Figure 1

shows the sensor purchased at Menards while Figure 2 shows the sensor pictured

at Meijer.

Notes: Menards price jumped recently to $14.99. Not sure why.

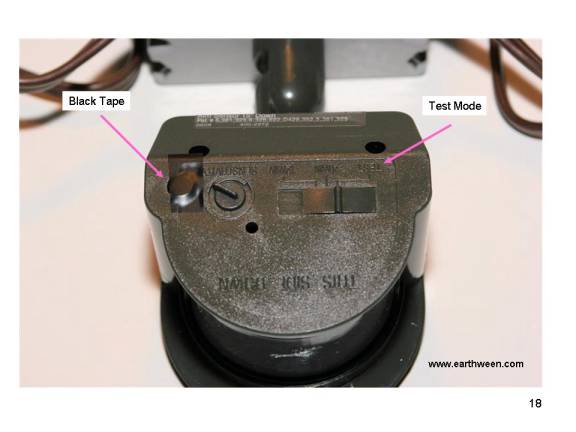

Figures 3 & 4 are views

of the same two sensors, contents removed from the box. Both sensors come with

3 electrical wire nuts.

Figure 3 depicts the Cooper

Lighting sensor that Menards carries. Cooper Lighting motion activated motion

sensor, model MS180 Bronze.

180 degree detection zone,

70 feet. 500 watts maximum load. Input, 120vac, 60hz.

Figure 4 depicts the Brinks

sensor that Meijer carries. Brinks motion activated replacement motion sensor,

model 7295B Bronze.

180 degree detection zone.

300 watts maximum load. Input, 120vac, 60hz.

Construction Overview

The construction of the

control isn’t that complicated. We basically connect the sensor to the outlet

box, cut the extension cord in two halves, connect the wires of the sensor to

the extension cord wires, put a cover on the outlet box, pretty much done.

All photos in the conduction

steps depict the Cooper Lighting sensor (as seen in Figure 3).

Step 1

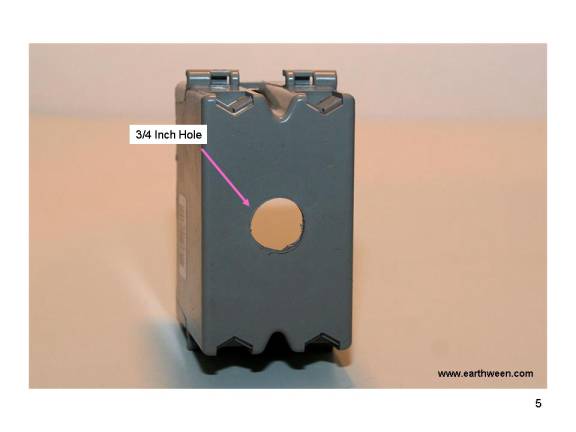

Drilling a Hole in the

Outlet Box

If your outlet box has predrilled

hole, you can skip this step.

Drill a 3/4 hole in the

center of the back of the outlet box. Make sure the holes are dead center (see

Figure 2).

Step 2

Connecting the Sensor to

the Outlet Box

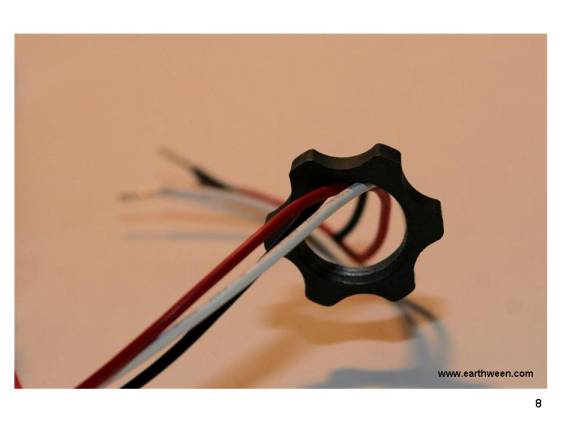

Unscrew the nut on the

sensor’s arm. Pass the three wires through the hole of the outlet box and screw

the arm of the sensor into the outlet box (Figure 6). The 3/4 inch hole will be

tight for sensor’s threads.

Figure 7 shows the sensor

completely screwed into the outlet box. Try to position the sensor (screw) so

that it ends up a horizontal position along with the outlet box as show in

Figure 7.

Step 3

Secure the Sensor to the Outlet Box

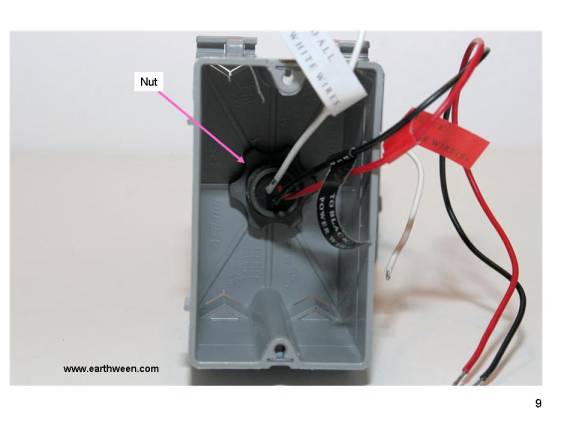

Pass the three wires inside

the outlet box through the nut of the sensor.

Screw the nut onto the

threads of the sensor arm until tight using your fingers only. No need to over

tighten the nut.

Step 4

Connect the Extension Cord

Cut the extension cord in

half using wire cutters as seen in Figure 10.

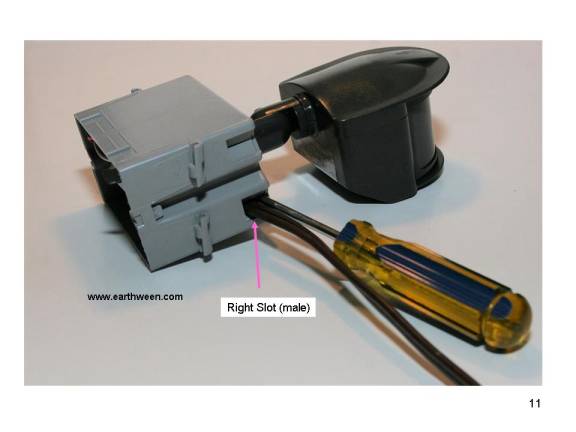

Using a Philips screw

driver, push the screw driver end through the outlet box slotted hole, bottom

hole, on the right side of the outlet box (right side when looking into the

open outlet box). The pass through the MALE end of the extension cord (the end

that was cut) into the outlet box as seen in Figure 11. It really doesn’t

matter which end of the extension cord ends up in which slotted hole, but for

consistency, I will reference the MALE side and FEMALE sides of the outlet box.

These sides represent the side the male or female end of the extension cord was

inserted.

Remove the screw driver once

the extension cord wire is passed through the slotted hole. Then repeat the

steps with the FEMALE end (the end that was cut) on the left side of the

control (left side when looking into the open outlet box).

Make sure you pull enough of

the extension cord halves into the box; about 6-8 inches of slack. Now separate

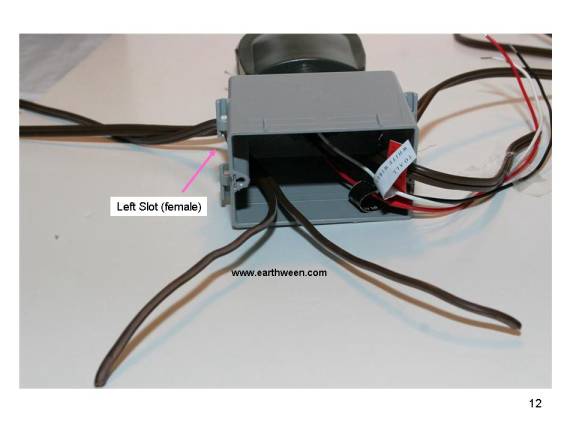

each extension cord wire into its two halves. Figure 12 shows the left

extension cord split into its two halves.

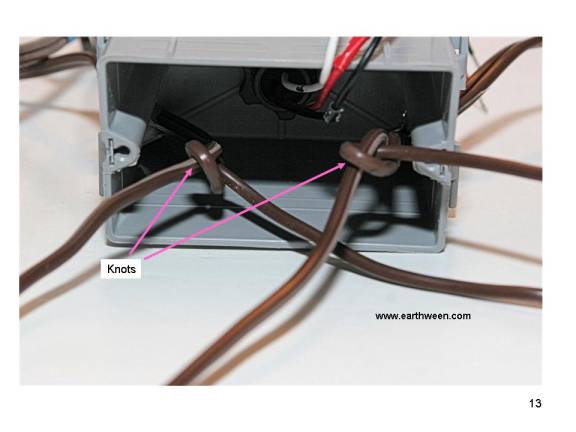

Tie a knot in both extension

cords, creating the knot as close to the inside of the outlet box as possible.

Then pull the other ends of the extension cords so that the knots are pulled

inside the outlet box, resting at the entrances of each slotted hole. These

knots will prevent/protect the extension cord wires from getting pulled out of

the outlet box.

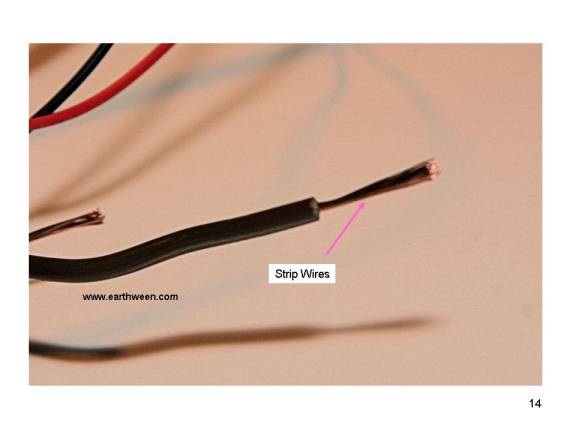

Now strip all 4 ends of the

extension cord wires leaving 1/2 inch of copper exposed as seen in Figure 14.

Step 5

Wire Connections

The sensor wires should be

pre-stripped of insulation at their ends. To insure a better connection, I

suggest stripping the ends a little more. Again,1/2 inch of copper should be

exposed.

The sensor directions

explain how to connect each of the sensor’s three wires to the wires of a light

fixture. Instead of connecting to a light fixture, we are going to connect the

wires to the ends of the extension cord.

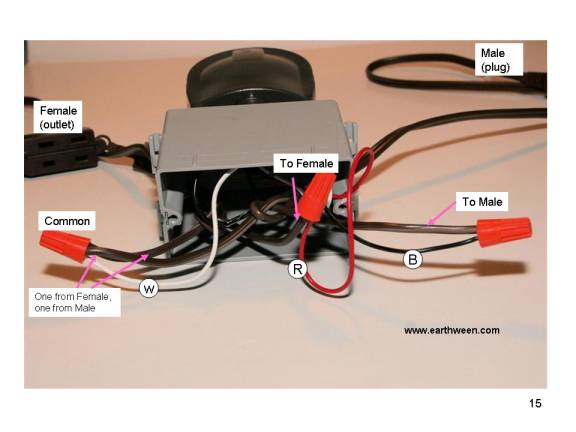

Refer to Figure 15 for this

following instructions on connecting the wires.

When connecting wire, twist

wires together in a clockwise fashion then screw on the electrical wire nut

onto the wires also in a clockwise direction.

1. Connect the white (W)

sensor wire to one wire of the female (left) extension cord pair of wires and

one wire of the male (right) extension cord pair of wires.

2. Connect the red (R)

sensor wire to the remaining female (left) extension cord pair of wires.

3. Connect the black (B)

sensor wire to the remaining male (right)

extension cord pair of wires.

4. Optional (not shown)…to

make the control a little more water proof, add a dap of clear silicon to the

inside of the wire nuts.

Step 6

Final Assembly

Tuck all wires into the

outlet housing as seen in Figure 16.

Attach the outlet cover as

seen in Figure 17.

Step 7

Cover the Light Sensor

Some sensors have a light

sensor to keep the control from activating in daylight (dusk to dawn setting).

“Why turn on a light in daylight” sort of thought. To insure this doesn’t

become an issue in the control, we cover the light sensor with some black tape

as seen in Figure 18. We want our control to work in daylight, darkness or

anything in between. Read the instructions of the sensor to find out all

features, functions, deviations of your particular sensor.

Most sensors have two

controls, one for sensitivity and one for “activation” time. Some sensors have

a “test” mode that allows the sensor to trip for a very short period of time,

4-10 seconds and then turn off and reset. These settings are ideal for

Halloween props, where we want the trigger to only last a moment. Read the

sensor manual for your sensor to get all of the details.

Testing

I suggest using a power

strip with a fuse and/or circuit breaker to prevent any possibility from

mis-wiring of the control.

1. Set the sensor’s

sensitivity to its maximum.

2. Set the sensor’s

activation time to “test” or its minimum.

3. Plug a lamp with a small

wattage blub; say 60 watts or less into the female (left side) of the control.

Then plug the sensor control into a live household outlet, giving the control

power.

Once you plug the control

into the outlet, the lamp should light for the specified duration of time.

Note: first time the sensor control is plugged in, there might extra time

applied to the activation upon first detection of motion. Read the instructions

of your sensor for exact behavior.

If your power strip trips a

breaker or blows a fuse, then you mis-wired something.

4. While the lamp is lit

(on), remain motionless and wait for the lamp to go out. The wave your hand in

front of the sensor. The lamp light should light up again. If it doesn’t, then

you mis-wired something.

Trouble Shooting

1. First place to look is

the red/black wire connections. Is the wiring correct? Red wire should be

connected to one of the female (left) extension cord pair of wires. The black

wire should be connected to one of the male (right) extension cord pair of

wires.

2. Manual Override Feature.

Some sensors have a manual override feature that allows you to turn on

(activate) what is plugged into the control (our lamp) by giving and taking

away primary power to the control using a timing sequence like on, off for a

second, then on again. This feature could be causing your test scenario some

issues. Refer to your sensors manual for more information.